Metalwork

Modified:

History

I chose Metalwork as a school subject and studied it for five years. I absolutely loved it – the process of shaping, cutting, joining, and polishing metal to create something beautiful or functional was incredibly rewarding.

We were taught the following:

- Measuring and marking

- Cutting and filing

- Sanding, buffing and polishing

- Riveting

- Soft soldering, brazing and silver soldering

- Welding

- Sheet metalwork – making brass vases and jugs

- Foundry work – casting parts for a bench vice

- Machining using the drill press, lathe and mill

- Thread cutting

The school featured a fully equipped metalwork workshop, including:

- 30 Workbenches with a vice and measuring, marking, cutting and filing tools

- 3 Lathes of different specification

- 2 Drill presses

- 1 Milling Machine

- 1 Foundry Furnace

- Welding & cutting area with an arc welder and oxy-acetylene cutting torches

- Brazing area with 3 oxy acetylene torches

- Additional tools

- Metal stock

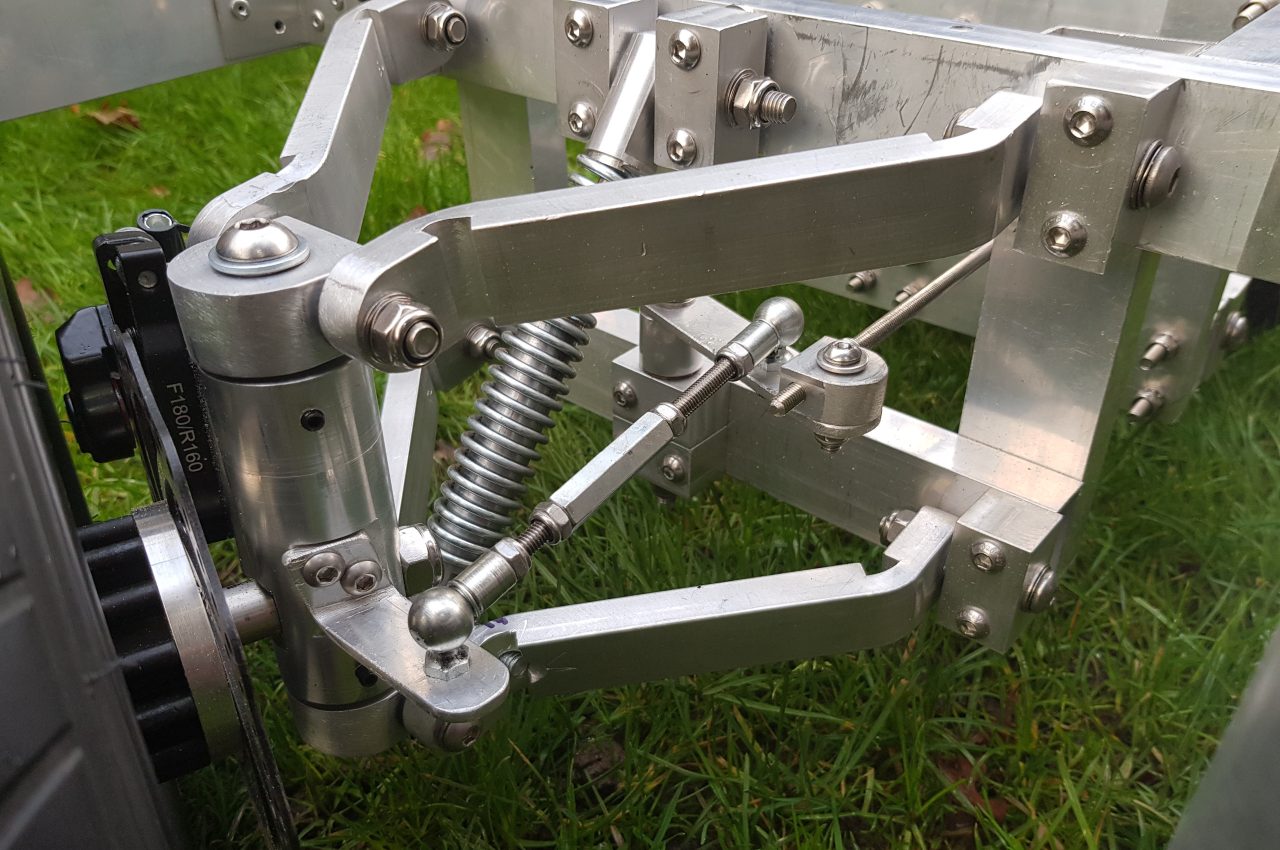

Over the years at school I created a variety of projects, culminating in a final-year project: A brass model of a vintage car, complete with functional steering and suspension.

My metalwork training has equipped me with a versatile skillset for making components for a wide range of engineering projects, including a remote-controlled electric cart for my daughter, a custom robot, a steam engine, or a housing for an electronic power supply. I can make brackets, shafts, arms… pretty much anything I need, including for home DIY tasks.

In 2020, shortly after moving into our house, I built myself a Workshop at the back of our garden. Over the last few years I have acquired additional tools and machinery. My interests in the metalwork domain include model engineering (functional rather than ornamental, for example a working stationary steam engine), among other things.

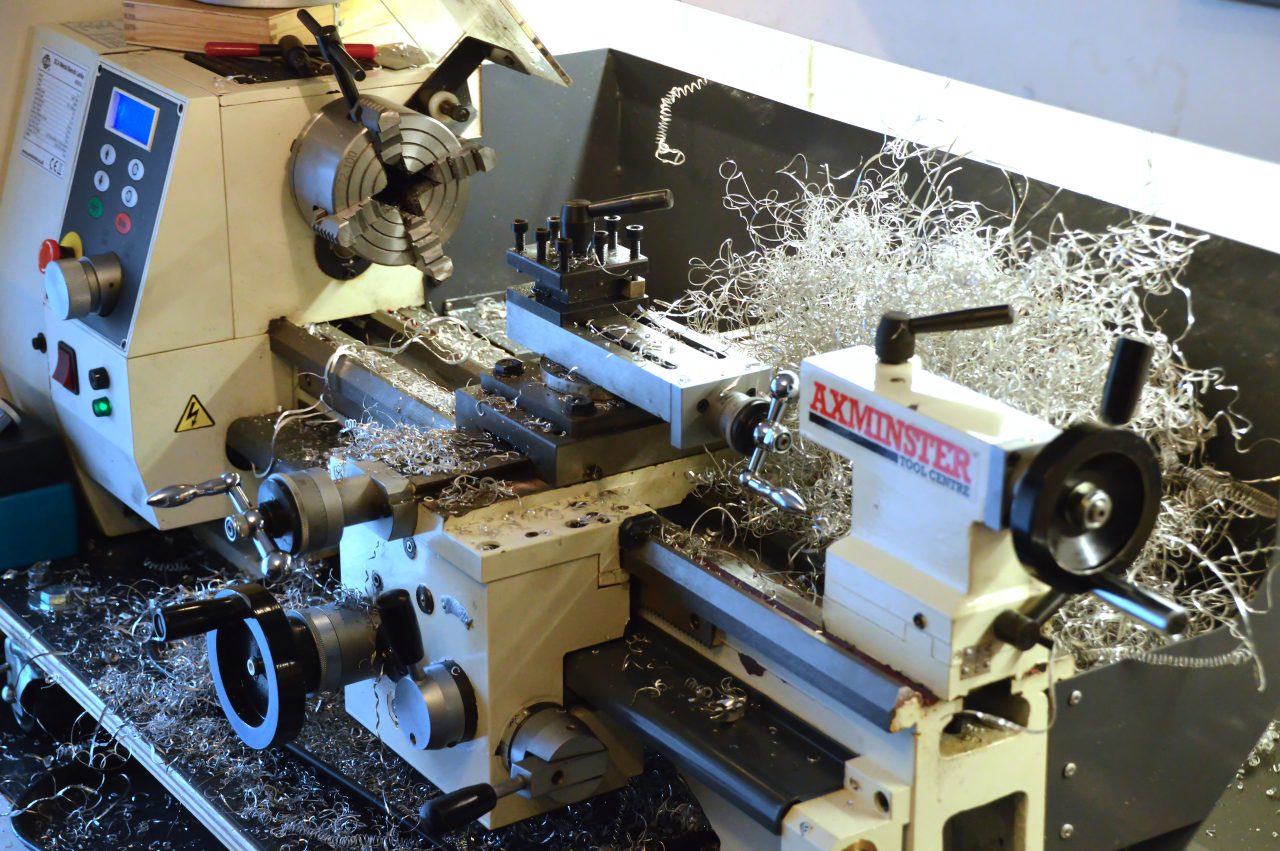

Axminster Sieg SC4 Lathe

For many years I have wanted to buy a metal lathe. In 2014 I finally had the space to keep and use one, so I bought a SIEG SC4, or as Axminster call it, the Engineer Series SC4, which is one of the larger, more powerful hobby lathes. It has a 1kW brushless motor with electronic control and ranges from 100 – 2000RPM.

The SC4 lathe is made by Sieg in China, and rebranded. My model is beige and branded Axminster. The new Axminster stock is green and light beige.

Specifications

| Centre Height | 105 mm |

|---|---|

| Chuck Fitting | Flange Mounted |

| Cross Slide Travel | 100 mm |

| Distance Between Centres | 510 mm |

| Headstock Taper | 3 MT |

| Leadscrew Pitch | 2 mm |

| Max Diameter over Bed | 210 mm |

| Nett Weight | 125 kg |

| Overall L x W x H | 1,000 mm x 550 mm x 400 mm |

| Power | 1.0 kW |

| Spindle Bore | 20 mm |

| Spindle Speed | 100 – 2,000 rpm |

| Tailstock Taper | 2 MT |

| Thread Pitch Range | 0.25 mm – 3.0 mm / 8 tpi – 24 tpi |

| Tool Shank Size | 10 mm |

| Top Slide Travel | 70 mm |

| Voltage | 230 V |

The motor is very powerful – I cannot stop the chuck with my hands even at 100 RPM! Don’t try that at home…

It features powered longitudinal and cross feeds, a moveable tailstock, and a size well-suited to most home workshop projects. Its metal gear set enables multiple speed options and precise synchronization, making it capable of cutting a wide variety of thread types.

I have mounted the lathe on a moveable board with steel angle brackets underneath as reinforcement, as you see in the above photo. My old workshop did not have much space, and if I needed to open the left cover panel to change the gears (manual operation), I needed to move the lathe. Now that it is in a larger workshop I could mount it directly to the bench, but having it on wheels allows me to move it for cleaning, and sets it at a good height, so I don’t have to bend over. I can lock the direction of the wheels as well apply a ‘parking brake’.

I have fitted the lathe with a 125mm chuck for larger work holding, as well as quick change toolpost. No other mods, except to remove the silly chuck guard.

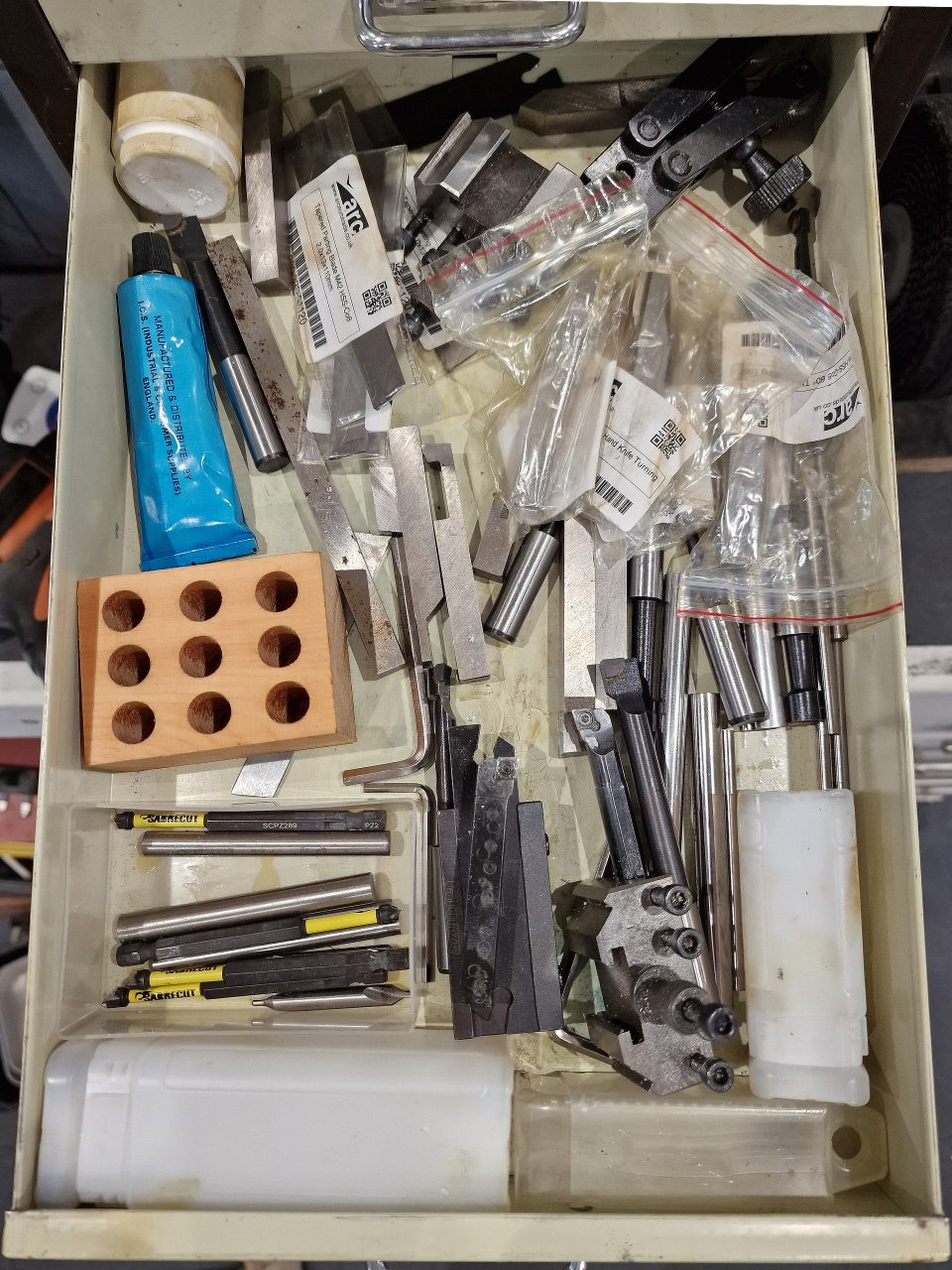

I have 3 sets of 10mm lathe tools: HSS, HSS Co5, and Glanze tungsten carbide tipped turning tools. The Glanze tools are awesome and cut through rusty cast iron with ease, where my HSS tools failed miserably.

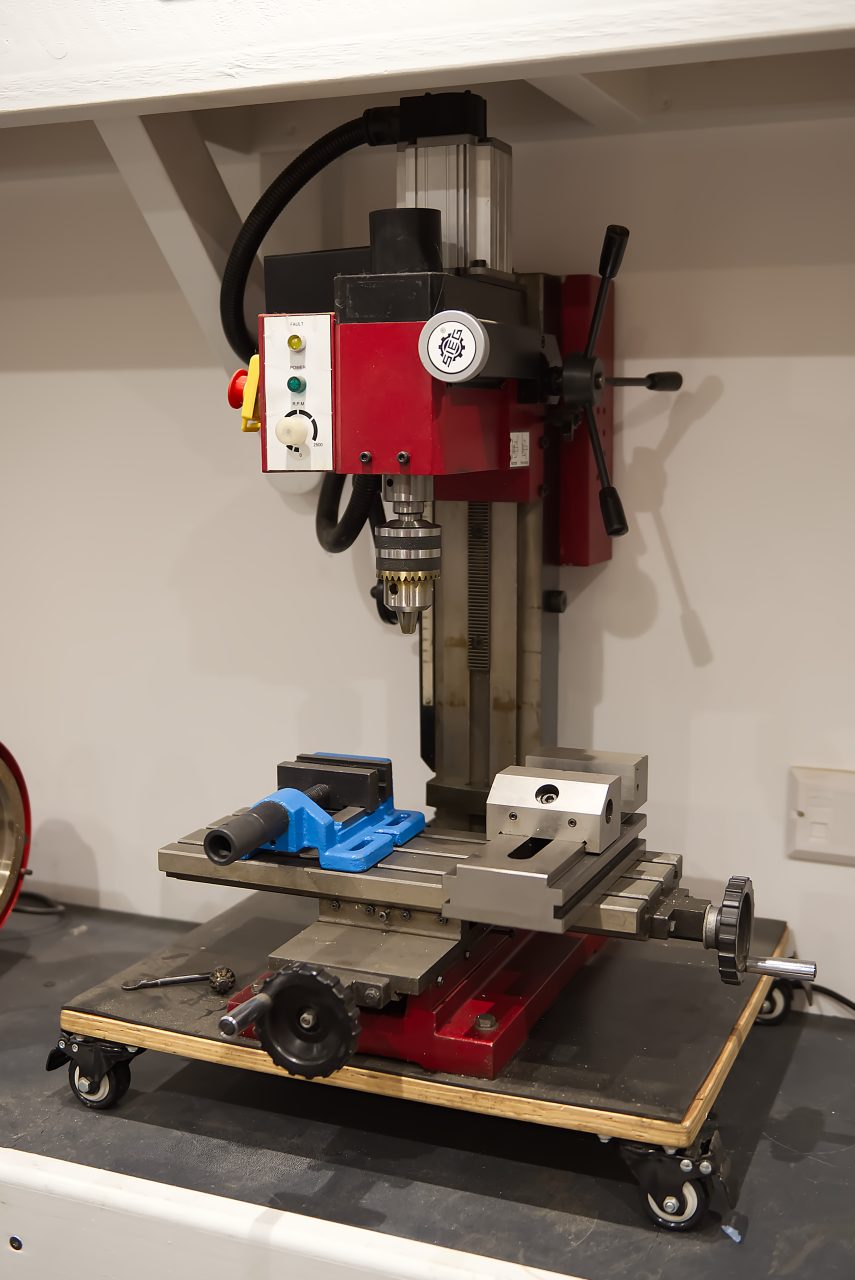

Sieg SX2P Mill

I have a SIEG SX2P milling machine, modified and sold by Arc Euro Trade. Axminster also carry the standard version rebranded. The Arc Euro Trade version features a larger table and a fixed, rigid column for improved stability. The machine is powered by a 500W brushless motor with electronic speed control. Thanks to the belt direct drive it is extremely quiet.

As for the lathe, I can’t safely stop it by hand at its lowest speed. Thanks to its belt direct drive, it’s exceptionally quiet in operation.

I have been meaning to install digital readouts (DRO) with display units to enable precise control over all three axes. I am also considering a CNC conversion, although that would require a significant investment of time and money – something for the future maybe.

Specification

| End Milling Capacity | 20 mm |

|---|---|

| Face Milling Capacity | 35 mm |

| Head Tilt | 45° – 0° – 45° |

| Lateral Table Movement | 100 mm |

| Longitudinal Table Movement | 220 mm |

| Max Drilling Mild Steel | 16 mm |

| Nett Weight | 50 kg |

| Nose of Spindle to Table [Max] | 280 mm |

| Overall L x W x H | 520 mm x 500 mm x 825 mm |

| Power | 500 W |

| Spindle Speed | 100 – 2,500 rpm |

| Spindle Taper | 3 MT |

| Spindle Travel | 180 mm |

| T Slot Size | 12 mm |

| Table Size | 390 mm x 100 mm |

| Throat | 170 mm |

| Voltage | 230 V |

These machines are useful for model engineering, but also allow me to make parts for a small vehicle, a robot or a spare part for something that has broken, for example a castor wheel for my wardrobe sliding door.

I have a collet chuck with a full range of ER32 collets, and I typically use this for milling rather than the chuck. I have a range of HSS, HSS-Co5 and carbide milling bits, cutting wheels and a boring head. I also have a Soba indexable rotary table, and a set of involute gear cutters. The mill comes with a set of mounting brackets and t-nuts and bolts, and I have purchased an angle plate and a tilting milling table.

Axminster AW315PD Pillar Drill

This is a great little machine – perfect for a home workshop. I previously used a drill press that you fit an electric drill into, but having a proper pillar drill is so much better. The slower speed and increased torque is better for drilling metal.

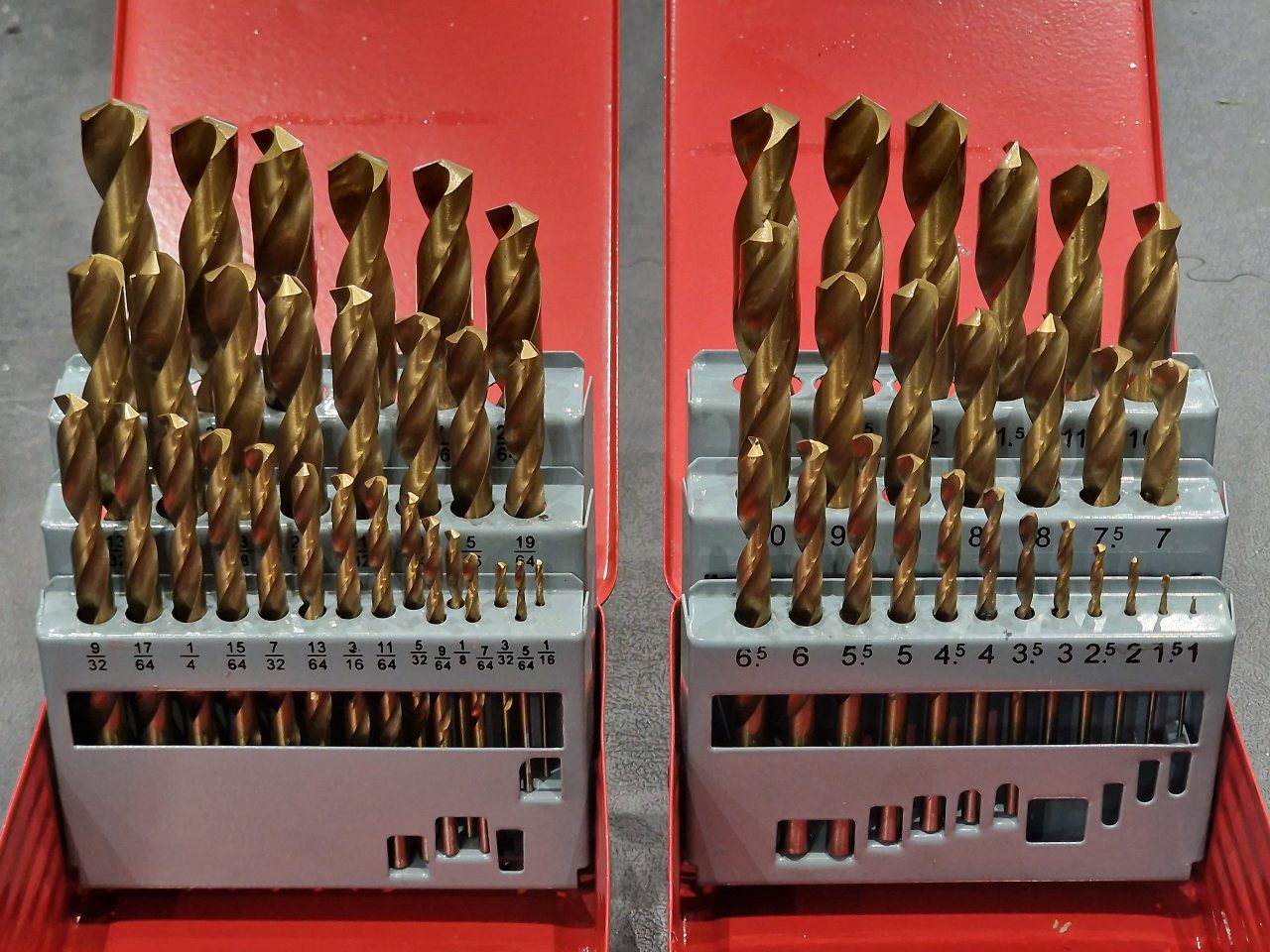

I have multiple imperial and metric drill bit sets, including HSS and full range of metric HSS-Co5 bits in 0.1mm increments.

Axminster Craft AC200BG Bench Grinder

This is a 550W grinder that spins at 2,850 RPM. I replaced the standard grinding wheels with CBN (Cubic Boron Nitride) wheels. CBN is second only to diamond in hardness, but does not react with iron at high temperatures like diamond does. These wheels provide a perfectly flat surface without the need for dressing.

They generate less heat than traditional wheels, have a much longer lifespan if looked after (no soft metal) and they are safer and won’t shatter if used properly. The side covers no longer fit, so I need to be careful during use. Even so, I feel a lot safer with these than standard silicon carbide wheels.

Ferm BGM1020 150mm Bench Grinder

My second grinder is 250W. I fitted adapters and buffing wheels to it, so that I can polish metal. When used with the appropriate buffing compound, it creates a perfect, shiny surface, provided you have finished it properly.

Other Metalwork Tools

In addition to the above machinery, I have the following metalwork tools:

- Forming

- VEVOR Single Horn 11kg Cast Steel Anvil

- Cobblers Anvil

- Parallel Pin Punch Sets

- Workholding

- Magnusson 150mm Swivel Workshop Vice

- Stanley MaxSteel 100mm Heavy-duty Swivel Bench Vice

- Stanley MaxSteel 75mm Multi Angle Vice

- Soba Premium Engineers Drill Vice 85mm wide

- Soba Unigrip Vertical / Horizontal 100mm Drill Vice

- Large & Small Precision Ground Steel Allen Key Milling Vice

- Cutting

- Clarke CPS200B 200mm Sheet Metal Shears

- Clarke CPS75 Mini Sheet Metal Cutter

- Stanley Fatmax Hacksaw

- Tinsnips

- Measuring & Marking

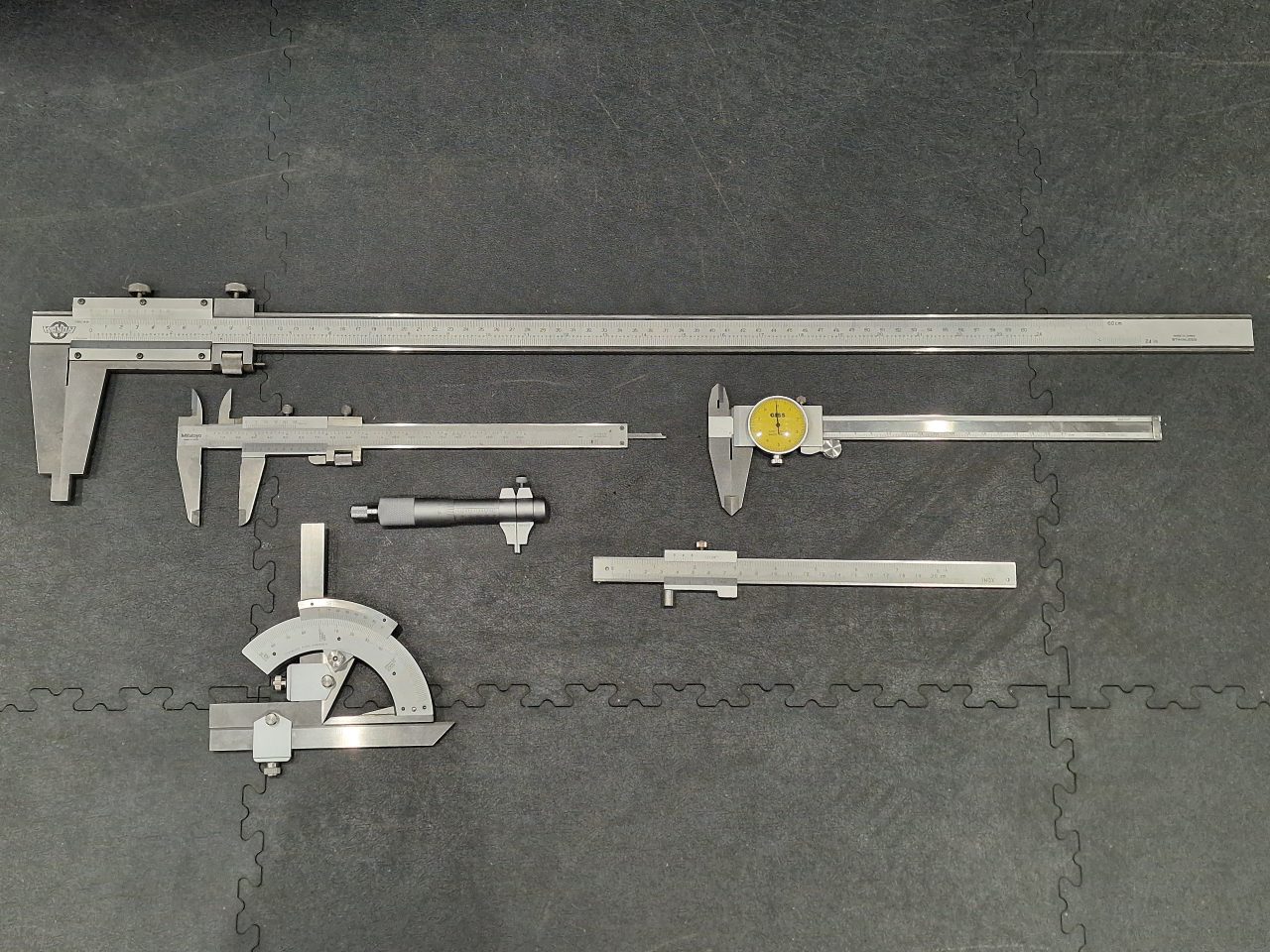

- Mitutoyo 500mm Vernier

- Kanon 1000mm Vernier

- Vernier Bevel Protractor

- Vernier Surface Gauge

- Arc Euro Trade Micrometer Set

- 30mm Dial Vernier

- Digital Vernier

- Tape Measures

- Thread Gauges

- Axminster Professional Steel Combination Square Set

- Steel Set Squares

- Steel Centre Squares

- Stainless Steel Rulers

- Scribers

- Calipers

- Centre Punches

- Letter & Number Punch Sets

- Thread Cutting

- HSS 25mm metric Die Set

- HSS Metric Tap Set

- HSS Co5 Tap and Drill Set

- Tap Wrenches and Die Holders

- Drilling

- HSS TiN Drill Bit Sets

- HSS Co5 0.1mm Increment Drill Bit Set

- HSS Drill Bits

- TiN Countersunk Bits

- Countersink Chamfer Deburring Drill Bit Set

- HSS TiN Step Drill Set

- Stroton Metric 6% Cobalt Step Drill Bit

- Stroton Metric M42 8% Cobalt Drill Bit set

- Tungsten Carbide Steel Double Cut Rotary Burrs Set

- Hand Reamer Set

- Power Tools

- Erbauer 18V Cordless Brushless Drills

- Erbauer 18V Cordless Brushless Angle Grinder

- Erbauer 18V Cordless Brushless Jigsaw

- Erbauer 18V Cordless Brushless Reciprocating Saw

- Ryobi Angled Die Grinder

- Fastening

- Metric & Imperial Socket Sets

- Wiha Screwdrivers & Nut Drivers

- Irwin T-handle Hex Key Set

- Metric & Imperial Combination and Ring Spanners

- Shifting Spanners

- Pipe Wrenches

- Knipex Pliers Wrench

- Screwdriver Bit Sets

- Allen Key Sets

- Brazing & Soldering

- Propane Torch

- Brass Brazing Rods

- Aluminium Brazing Rods

- Soft Solder & Flux

- Finishing

- File Sets

- Emery Cloth – Various Grit Sizes

- Steel Wool

- Flap Sanding Discs

- Lathe Tools

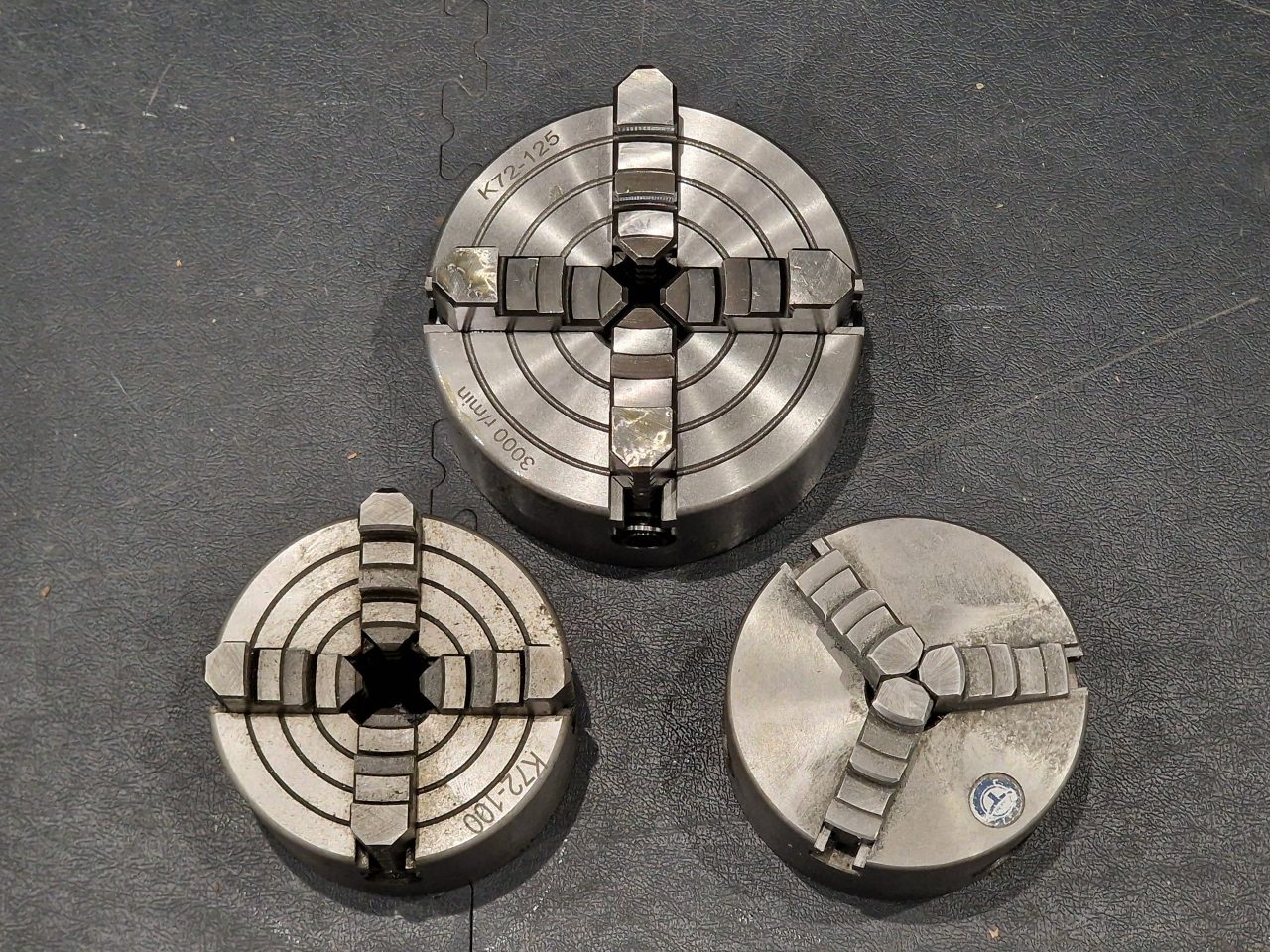

- 100mm 3-Jaw Self Centering Chuck

- 100mm 4-Jaw Independent Chuck

- 125mm 3-Jaw Self Centering Chuck

- 125mm 4-Jaw Independent Chuck

- Face Plate

- Various Arbours

- Mill Tools

- Collet Chuck

- ER32 Collet Set

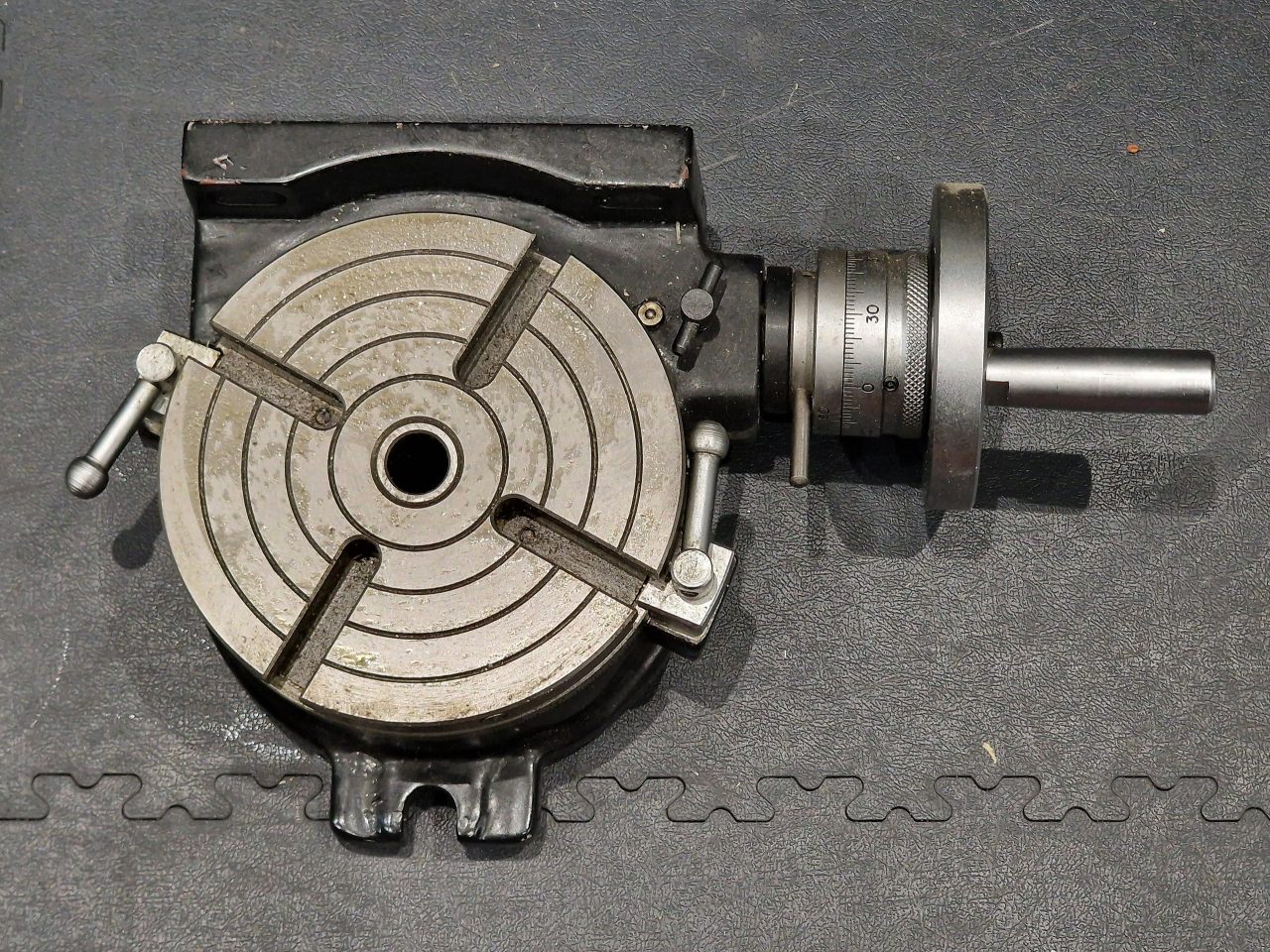

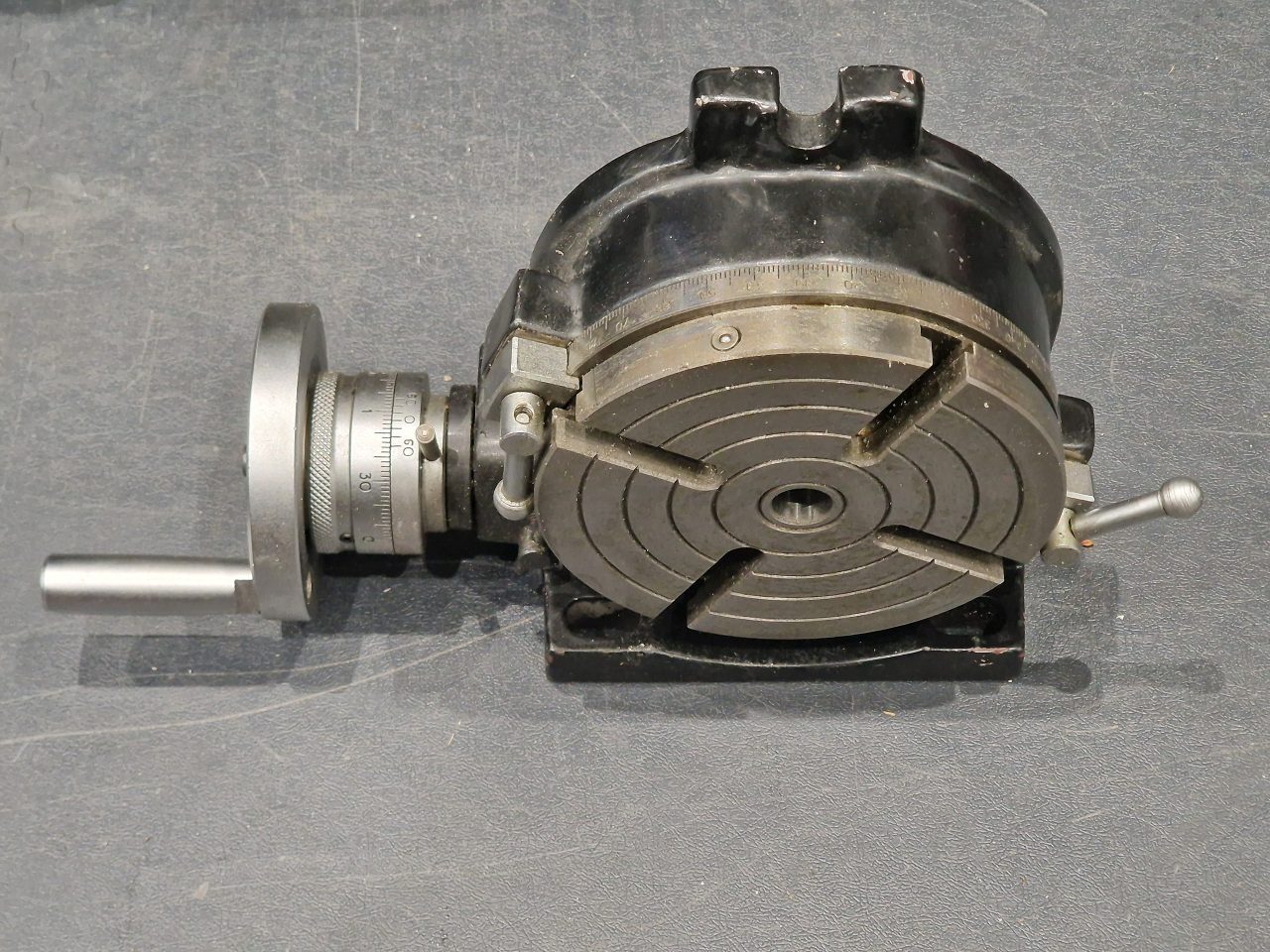

- Indexable Soba Horizontal & Vertical Rotary Table

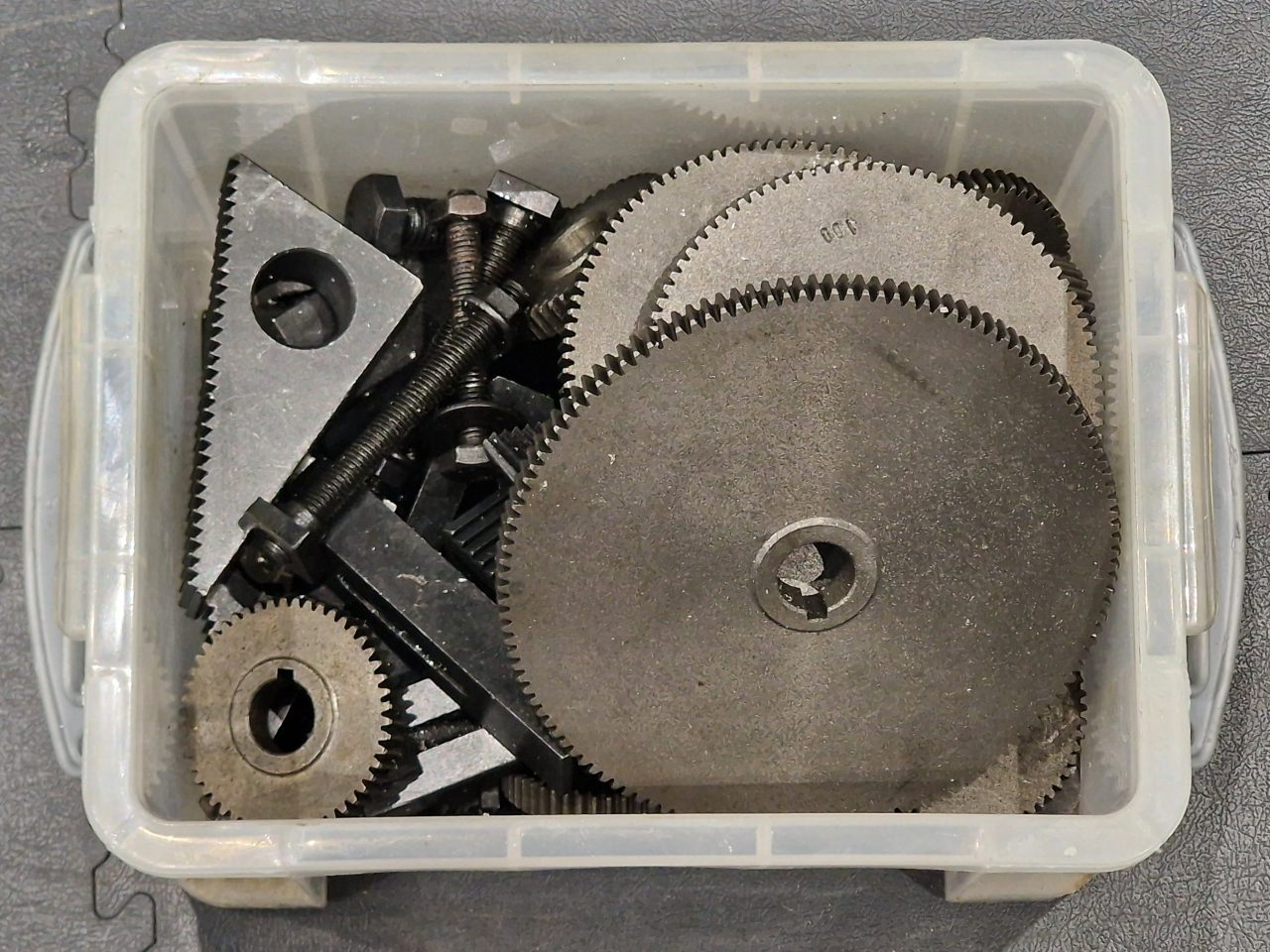

- Involute Gear Cutting Set

- Tilting Milling Table

- Angle Plate

- Slitting Saw Arbour and Blades

- Welding

- I plan to purchase a TIG welder in future

Gallery